> Products > Roll Forming Machine > Channel(purlin) for building

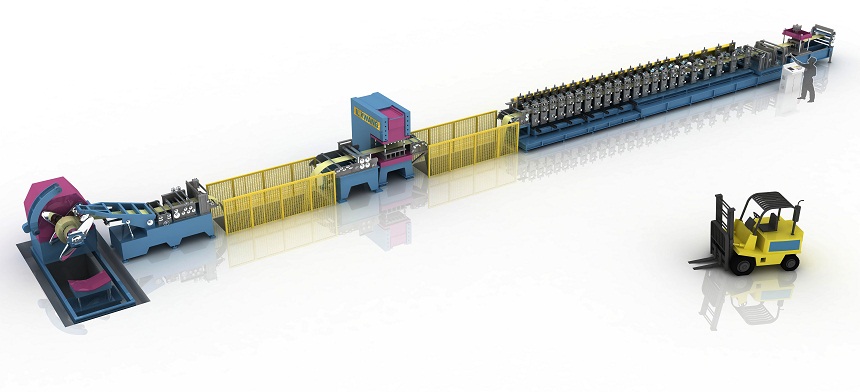

Channel(purlin) for building

This Roll forming machine for channel(purlin) is manufactured based on the world’s top technology and experiences, and Roll forming machine for channel(purlin) has high durability and convenient management. It exquisitely designs diverse wave forms to meet customers’ requirement, and produces continuously and conveniently world’s top purlin products of C. Z., Omega (Rack), Sigma shape as well as guardrails for road.

Roll forming machine for channel(purlin) consists of Un-coiler that inputs and releases coil, Pinch Roll & Leveling System that exquisitely inputs coil, N.C Feeder & Punching Unit that punches and notches the input coil precisely, Roll Forming Unit that makes shape through Multi-stage Forming Roll, and Shearing Unit that cuts fabricated C & Z panel.

<Specification>

| 1. | Raw Material:Cold Roll Forming Machine | ||

| 2. | Coil Thickness | : | 1.5 ~ 4.0mm (±0.02) |

| : | ASTM A 653M Grade SS 340 Class 1 | ||

| : | Yield strength 345Mpa for HR, CR, Galvanized | ||

| 3. | Coil Width | : | 180 ~ 500mm |

| 4. | Producing line speed | : | Max. 25Meter / min |

| ( In case of longer than 5 meter length product With confirmed punching pattern by buyer and seller) | |||

| Speed control | : | Frequency control | |

| 5. | Electric power source | : | 380V x 50Hz x 3Ph (Buyer’s option) |

| Control voltage | : | According to customer’s specification | |

| Total power | : | 80Kw | |

| 6. | Product | ||

| Width | : | +/- 1mm | |

| Length Tol. | : | +/- 1mm | |

| Twist Tol. | : | +/- 2mm at middle for 7meter | |

| Angle Tol. | : | +/- 1.5 degree at 300mm from end of profile | |

| Flare Tol. | : | +/- 1.5 degree at 300mm from end of profile | |

| Minimum length | : | 1500mm ( In case of shorter than 1.5meter, it should be taken out manually in slow speed.) | |

| Maximum | : | 12,000mm | |

Un-Coiler

Un-coiler is a device that inputs steel coil to feed it stably to the equipment.

Using Coil Car can makes easy to load and change the Coil and the mandrel shafts expand and contact operates by a hydraulic.

Pinch Roll & Leveling System

The device stably supplies steel coil fed from Un-coiler to Punching System, inputting it to the equipment and leveling precisely.

To control the elasticity and get loosing of coil there is coil opener has installed and as well as the leveling unit to ensure the flatness. And consists the front shearing unit operating by hydraulic to help the replacing the coil and products.

N.C.Feeder & Punching Unit

It precisely punches and notches to the input coil, and punches and notches various exquisite and functional structures required by C&Z purlin material.

In order to satisfying with various notching pattern and helping for mass production the automatic control system for precision punching unit has developed.

Roll Forming Unit

It provides aesthetic shape through multi-stage forming roll and microwave forming roll, and in case of choosing Cassette Type or Double Layer Type, more diverse shapes like U-bar, Track can be formed at single equipment.

In addition, an automatic width adjusting system has applied for produce a variety of products by changing the width and height.

Shearing Unit

It precisely cuts and discharges products. Various ways can be applied, depending on the required output such as GO&STOP, Shear Manufacturing and Fly-type Shear Manufacturing.

Profiles: Roll forming machine for channel(purlin)

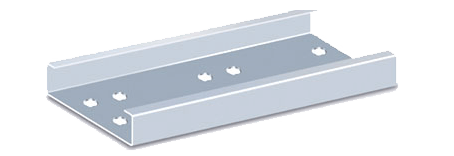

IKPUR-RACK

- Coil width : 600~900mm

- Product width : 220~300mm

- Coil thickness : 1.6~2.5mm

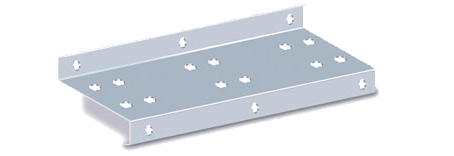

IKPUR-C300

- Coil width : 250~500mm

- Product width : 120~300mm

- Coil thickness : 1.2~3.2mm

IKPUR-Z300

- Coil width : 250~500mm

- Product width : 120~300mm

- Coil thickness : 1.2~3.2mm