> Products > Roll Forming Machine > Automobile

Automobile

Automobile Frame

The equipment is manufactured based on the world’s top technology and experiences, and Roll forming machine for Side member is equipped with high durability and convenient management. It forms U Bar and G. V. Side Member of 6 ~ 12mm thickness for commercial vehicles and the following equipment has been installed for Hyundai Motor Company in Korea, China and Asia Motor Group (AMW) abroad

Recently, the molding method is applied and recognized as the most suitable for auto parts production facility after covering the pressing type.

Our Roll forming machine for Side member is based on 25 years of continuous technical development to produce the production of precision assembly of automotive products in accordance.

The thickness and width of the material senses are committed to the production and automatically changes to the production of complete sets of equipment for all products.

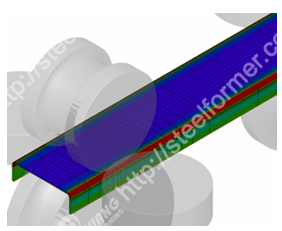

The forming rollers have been designed based on the structure calculation program for considering the sufficient rigidity of side members.

Developed so that they can be processed at the same time forming part of the secondary processing such as punching, bending characteristic even after molding of auto parts

Roll forming machine for Side member consists of Un-coiler that inputs and releases coil, Pinch Roll & Leveling System that exquisitely inputs coil, Roll Forming Unit that makes shapes through Multi-stage Roll Forming Unit, and Shearing Unit that cuts the fabricated products.

<Specification>

| 1. | Raw material | : | IRSM44 (BSK 46, Domex 550-600, hot rolled alloy steel) in coil Y.P is from 450 ~ 650Mpa T.S is from 500 ~ 800Mpa |

| 2. | Specification of raw material | ||

| Applying thickness | : | Min. 5mm ~ Max. 10mm (±0.05mm) | |

| Coil Weight | : | Max. 10ton | |

| Coil I.D. | : | 508 and 610mm | |

| Coil. O.D | : | Min.1200mm and Max.2000mm | |

| Coil width | : | Min.340 ~ 560mm | |

| 3. | Product specification | ||

| Thickness | : | Max. 5.0mm to 10mm | |

| Web (Width) | : | 240mm to 350mm | |

| Flange (height) | : | 60mm to 100mm | |

| Length | : | 4000mm to 12,200mm | |

| Feature of profile | : | As follow | |

| Tolerance of profile | : | As follow | |

| Radius | : | 12mm | |

Un-Coiler

Un-coiler is a device that inputs steel coil of 6mm ~ 12mm to feed it stably to the equipment.

Using Coil Car can makes easy to load and change the Coil and the mandrel shafts expand and contact operates by a hydraulic.

Pinch Roll & Leveling System

The device stably supplies steel coil fed from Un-coiler to Punching System, inputting it to the equipment and leveling precisely.

To control the elasticity and get loosing of coil there is coil opener has installed and as well as the leveling unit to ensure the flatness. And consists the front shearing unit operating by hydraulic to help the replacing the coil and products.

Roll Forming Unit

It provides aesthetic shape through multi-stage forming roll and microwave forming roll.

In addition, an automatic width adjusting system has applied for produce a variety of products by changing the width and height.

Shearing Unit

It precisely cuts and discharges products. Various ways can be applied, depending on the required output such as GO&STOP, Shear Manufacturing and Fly-type Shear Manufacturing

Automobile Exterior

The equipment is manufactured based on the world’s top technology and experiences, and Roll forming machine for Automobile Exterior is equipped with high durability and convenient management. It can produce quality automobile exterior steel plate continuously and economically.

The forming unit with the best high precision technology, it can produce the products that consumers want.

Roll forming machine for Automobile Exterior consists of Un-coiler that inputs and releases coil, Pinch Roll & Leveling System that exquisitely inputs coil, Roll Forming Unit that makes shapes through Multi-stage Roll Forming Unit, and Shearing Unit that cuts the fabricated products.

Un-Coiler

Un-coiler is a device that inputs steel coil to feed it stably to the equipment.

Using Coil Car can makes easy to load and change the Coil and the mandrel shafts expand and contact operates by a hydraulic.

Pinch roll & Punching system

The device stably supplies steel coil fed from Un-coiler to the system, inputting it to the equipment and leveling precisely.

Roll forming unit

It is a device that cuts automobile exterior steel plate, cutting precisely the wave form derived from Multi Stage Roll Forming Unit

Shearing unit

It precisely cuts the completed automobile exterior steel plate and discharges. Various ways can be applied, depending on the required output such as GO&STOP, Shear Manufacturing and Fly-type Shear Manufacturing.