> Products > Sandwich Panel Production Line > Polyurethane sandwich panel line (Continuous)

Polyurethane sandwich panel line (Continuous)

Polyurethane Sandwich Panel Line is the automation equipment that can continuously and efficiently produce polyurethane sandwich panels of exquisite and diverse shapes. This Sandwich panel line has the advantages such as high durability, easy management, technology equivalent to those of advanced European companies and relatively competitive price, and it is the excellent facility that has been exported to Europe, Asia, Middle East, Russia and so forth as well as domestic market and is well received from customers.

Our PU sandwich panel has high strength and durability of insulating ability. In addition, we use the PIR (Poly Isocyanurate) which it has the resistance to flame so the panel has the high resistance to flame. Also HCFC-14b the blowing unit as well as the Pentane the eco-friendly material will make more safety and better environment as it’s the “GREEN” unit.

Polyurethane Sandwich Panel Line consists of Un-coiler that inputs and releases coil, Roll Forming Unit that makes shape of coil, PU Forming Unit that sprays PU solution, Laminating Unit that makes the shape of sandwich panel, Panel Cutting Unit that cuts the fabricated sandwich panel, Cooling Conveyor Unit that finishes products hardening the cut panel sufficiently at intervals, Auto Stacking Unit that loads the finished panels, and Panel Packing Unit that packs the loaded panels with plastic wrap and discharge them.

Un-Coilers & Entry parts

Un-coiler is a device that inputs steel coil to the upper and lower parts of sandwich panel to feed it stably. The mandrel type operated automatically by a hydraulic and it’s convenient to control and sophisticated. 2+2 system production equipment unit doesn’t need to stop to load the new coil set, which it helps to continue to produce high capacity of panels.

Roll forming machine

It is a device that continuously gives shape to sandwich panel as steel coil fed from Un-coiler is engaged between the upper and lower sections of a metal roller.

Usually it makes the beautiful and delicate shape of variety wall and roof type panel. It designed in cassette type and rail way wheel type to easily change to make different shapes.

Polyurethane foaming system

It consists of the nozzle and pump that spray polyurethane solution, a tank that stores solution, various catalysts and gas, and a traverse that enables to spray PU solution evenly, and the device is designed considering high precision and the reliability of maintenance. A convenient control panel is equipped with for users’ easy control of various data required for foaming process.

It equipped with a convenient control panel (Control panel) so that you can easily adjust the various data required for the firing process.

Laminating unit

It is a device that makes the shape of sandwich panel applying constant pressure and heat to the upper and lower steel plate foamed with polyurethane.

It designed in perfect structure that has a stiffness and durability and as well as the side blocks to enable the rapid of product replacement.

<Specification : sandwich panel line>

| 1. Producing speed | : | Min. 2meter/min ~Max. 15meter/min |

| 2. Length of Double belt conveyor | : | 20~40meter |

| 3. Factory Electricity | : | 380V x 50Hz x 3Ph (User’s choice available) |

| 4. Controlling Electricity | : | A.C. 220V (User’s Choice Available) |

| 5. Factory’s Area | : | 130~150(Length) x 30m(Width) x 6m(Height) |

| 6. Pressure of compressed air | : | Over 6 bar required |

| 7. Production | : | 4~5 person |

<The general specification of PU panel produced>

| 1. Panel length | : | Min. 2,000mm in auto mode Max. 18,000mm (±3mm) |

| 2. Effective width | : | 1000mm for roof 600mm~1200mm for normal wall |

| 3. Panel thickness | : | Available thickness from 30~200mm (depended upon heights of the side sealing block.) |

| 4. Top and Bottom layer | : | Pre-painted Galvanized coil For ASTM A 526-85, JIS G 3302 SGCC Thickness = 0.4mm ~ 0.7mm |

| 5. insulation | : | PUR hardened and PIR / Pentane |

| 6. Density of Insulation | : | 30kg/m3 ~ 50kg/m3 |

Profiles: Polyurethane Sandwich Panel Line (Continuous)

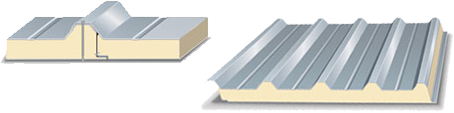

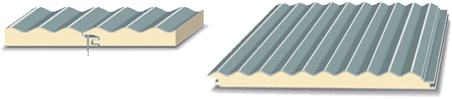

IKPU-RF-5R

- Coil width : 1219/1070mm

- Product width : 1000mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

- Depth of Roof : 38mm

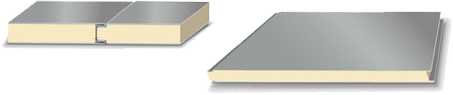

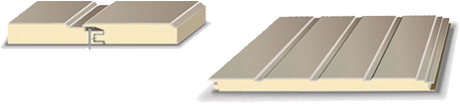

IKPU-WA-F

- Coil width : 1070/1070mm

- Product width : 600~1200mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

IKPU-WA-P

- Coil width : 1070/1070mm

- Product width : 600~1200mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

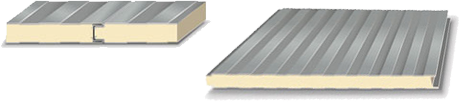

IKPU-WA-M

- Coil width : 1070/1070mm

- Product width : 600~1200mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

IKPU-SF-F

- Coil width : 1205/1070mm

- Product width : 800~1000mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

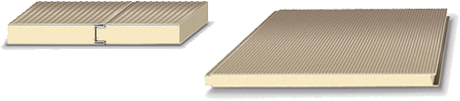

IKPU-SF-1R

- Coil width : 1205/1070mm

- Product width : 1000mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

IKPU-SF-3R

- Coil width : 1219/1070mm

- Product width : 1000mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

IKPU-SF-C9O

- Coil width : 1250/1070mm

- Product width : 1000mm

- Panel thickness : 50~200mm

- Coil thickness : 0.4~0.7mm

Tags : Polyurethane sandwich panel machine, Polyurethane sandwich panel line, PU Sandwich Panel Line, Sandwich Panel Machine